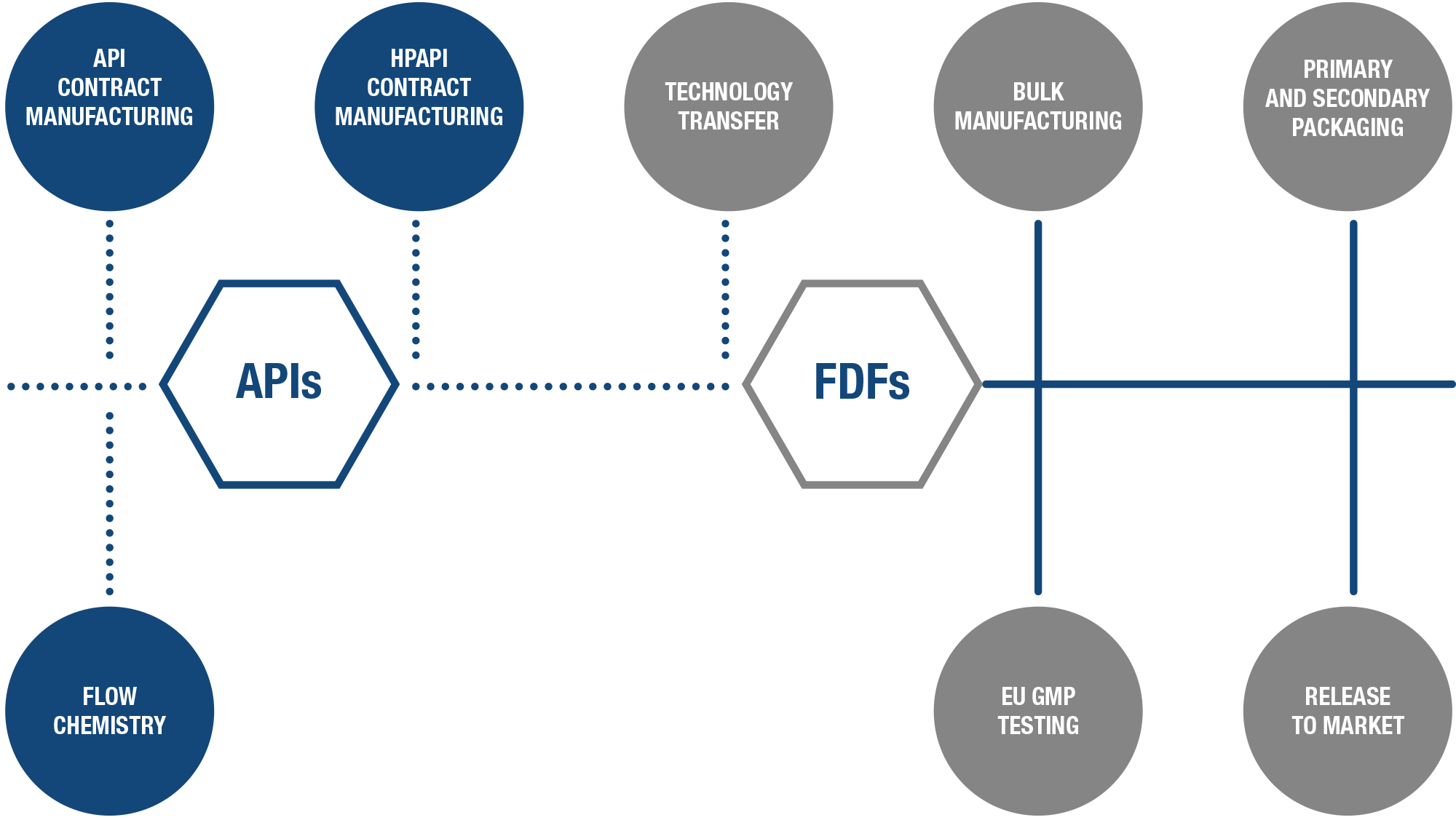

Tailor-made Solutions in contract services to maximize your portfolio and sales.

The strategic planning and location in Malta of Medichem and Combino Pharm allow the launch of our products to the market from the first day after the expiration date of the patent.

Being the first to launch is key to achieving optimal market penetration.

TAILOR-MADE SOLUTIONS

As your business partner, we know that being first to launch is key to achieving optimal market penetration for this reason we offer tailor-made solutions in contract services to maximize your portfolio and sales.